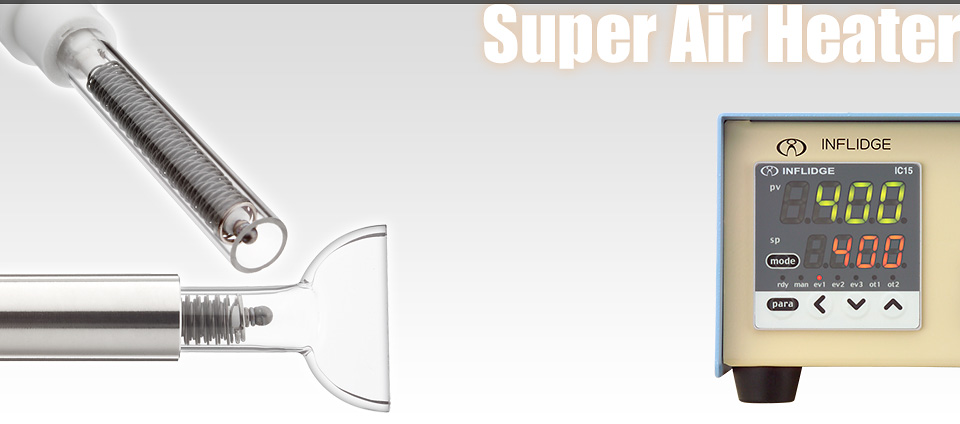

Air Heater

Overview

Product Lineup

- Super Air Heater SEN (Built-in Sensors)

- Super Air Heater MAX (Built-in Low Flow Seasor)

- Super Air Heater SAH (Metallic Base Type)

- Super Air Heater SAH (Ceramic Base Type)

- DFC-20E Digital Flow Controller (Temperature Control, Flow Meter)

- Digital Temperature Control Unit DAC-8E

- DAC-84E Multiple Temperature Control Unit

Advantages

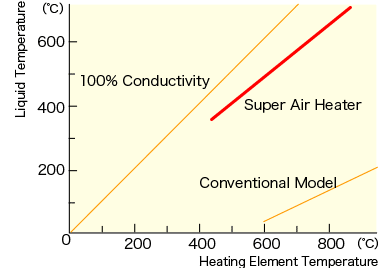

- High temperature

- Long life

- High-speed heating

- Electricity-saving, energy-saving

- Accurate control of temperature

- Heating of localized areas possible

- Use of nitrogen gas possible

- Does not use flames, and emits no contaminants

- Compact and lightweight

- Special orders accepted (nozzle, heater capacity, dimensions, etc.)

Applications

- Tip on soldering robots

- Automatic soldering of electronic parts

- Soldering of ceramic and glass substrates

- Drying adhesive, ink and paint

- Automation of small part and marking drying

- Automation of resin bending and resin caulking

- Burr removal for molded resin parts

- Preheating electric cable conductors

- Sealing for automatic vinyl packaging machines

- Automatic adhesion for wire coils

- For use with bga reworks and repairs

- Soldering of solar battery panels

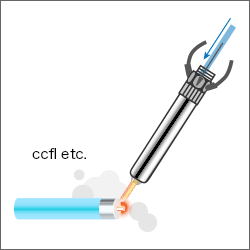

- Drying and caulking backlights (ccfl) on LCD panels, etc.

- Heat source for simple reflows, etc.

- Heat source for bobbin coils and other wire coils

- For use in attaching internal panels to car doors

Soldering

Spot Soldering

- Enables micro-spot heating in accordance with the shape of the nozzle.

- Minimizes the effects of heat on other parts.

- Heat volume easily adjusted by changing the temperature and air flow.

- Swift temperature increase to enable intermittent heating.

- Soldering of flexible substrates and minute parts.

Heat Caulking

Preheating

- Preheats micro-spots before they come into contact with the soldering iron to produce excellent soldering results while using minimal energy.

- Localized heating so that other parts are not affected.

Glass Processing

Glass Processing Preheating

- Suitable for preheating localized areas that are to be processed with burners.

- The heater can be turned on and off to minimize energy loss.

- Chip-off preheating.

- Enables micro-spots to be preheating evenly.

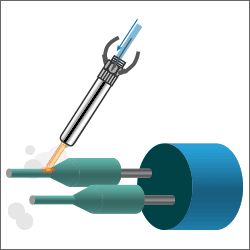

Shrink Tube Heating

Heat-shrink Tube Heating

- Suitable for heat-shrinking minute parts and wire clusters.

- Enables the localized heating of tubes.

Cosmetic Finishing

Cosmetic Finishing

- Adds a gloss finish to cosmetics.

- Heat volume easily adjusted.

- Enables high-grade duplicated processing.

- Enables clean, localized heating with air.

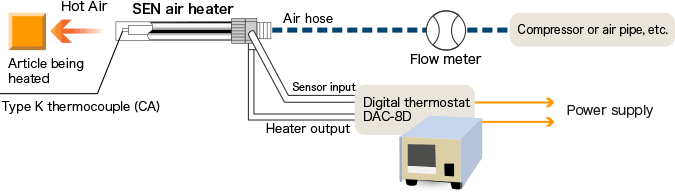

Usage

Air heaters supply hot air at a maximum temperature of 800 degrees Celsius.

Uses a special heating element (Kanthal wire) to increase temperatures at high efficiency within a short period of time. The compact design allows them to be attached neatly.

SEN-type built-in thermal sensors are used, which in combination with the thermostat enables the temperature to be controlled accurately.

This allows manufacturing conditions to be reproduced in a favorable manner.

Also, the built-in thermal sensor monitors the heating status, etc., which is useful for the circuits and work procedures set up by the customer for safety purposes.